The Pipeline market has historically been accustomed to vehicles with hydraulically controlled components, in the belief that they provide sufficient reliability and ease of intervention in the event of malfunction.

Regarding this project, our aim has been to develop a vehicle with high reliability, improved performance and lower consumption. With the help of electronic controls, we have managed to achieve high safety standards while improving operator comfort. Finally, an advanced telematics system allows preventive maintenance management, providing the opportunity to manage servicing effectively and efficiently.

Working closely with the customer and using Danfoss components we created a new revolutionary machine.

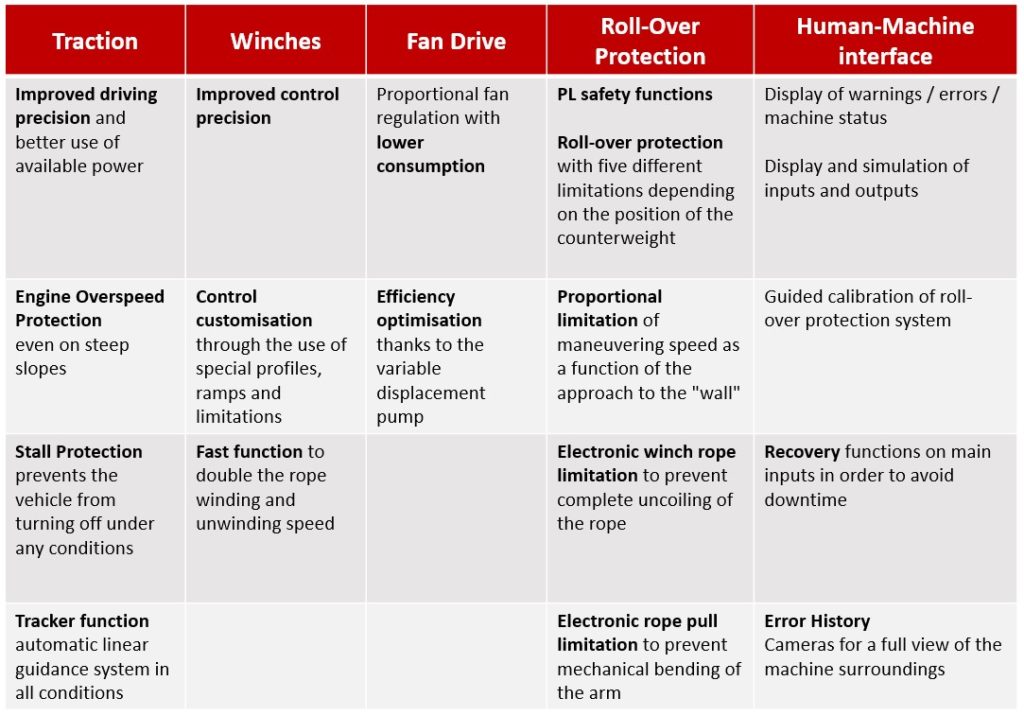

The new innovative pipelayer system achieves all its objectives in terms of:

- Safety: the PL certified system guarantees the necessary safety standards. In addition to this, thanks to cameras located on the vehicle blind spots, the operator inside the cab has a 360° view of the machine surroundings and total control over the situation.

- Comfort: increased thanks to increased driving precision and the removal of hydraulics in the cab.

- Performance and consumption: timely management of available power optimises and improves vehicle performance as well as ensuring lower consumption.

- Human-Machine interface: the on-board telematics make it possible for the operator and the control centre to access machine parameters in real time.

- Reliability: the operator has all the main machine parameters at his fingertips, from temperature to pressure, thanks to the state-of-the-art display. Warning and error indications are clearly visible and timely. Not only that, but an advanced telematics system allows preventive maintenance management, providing the opportunity to manage servicing effectively and efficiently.

Macro-function improvements